Harley Davidson Exhaust Bolt Torque

Harley-davidson Torque Spec Chart.

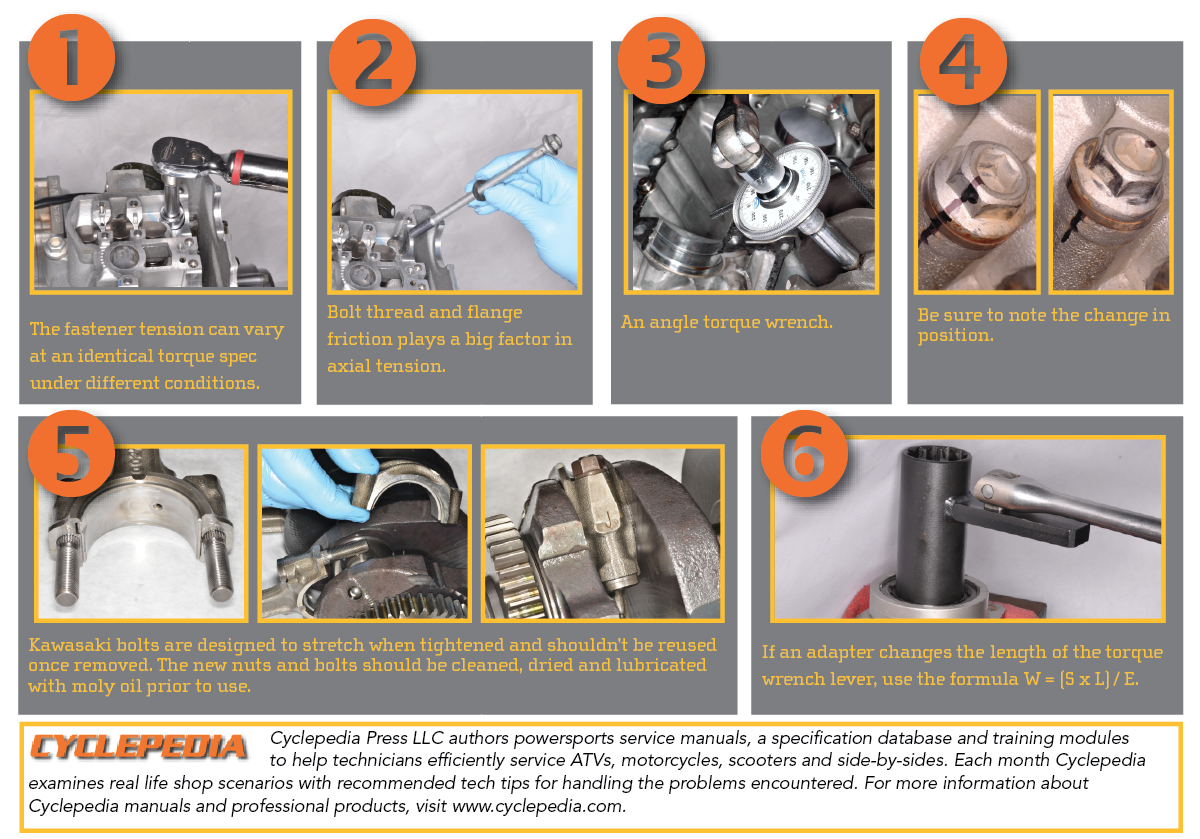

Harley davidson exhaust bolt torque. 8 - 14 in. If applicable remove OEM O2 sensors from the OEM pipes and install in both front and rear. This table is based upon Grade 5 fasteners generally used Harley-Davidson motorcycles.

Tighten each bolt to 12-15 foot pounds of torque. First you should pre-load the bolts to about 16 foot-pounds. 9525 mm Stroke - 400 in.

Exhaust bolt torque spec. Reveal the Exhaust Pipe Opening. Axle nut is set at 50 FOOT lbs.

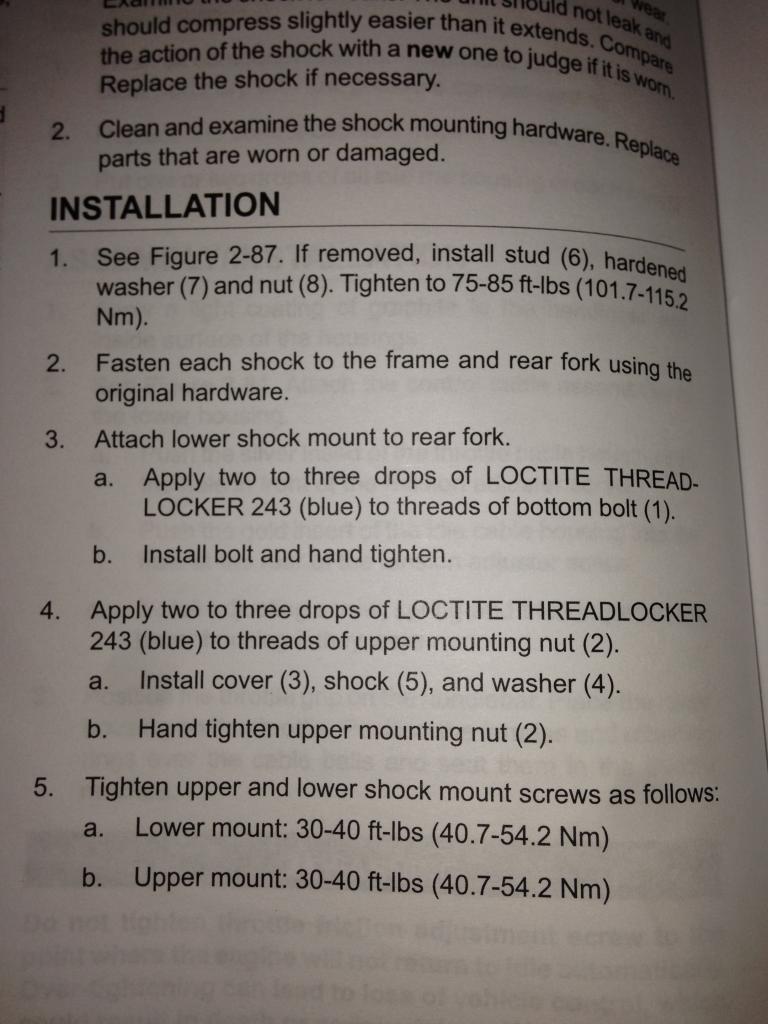

Tighten the top nut of the front cylinder head exhaust flange to 9-18 in-lbs 1-2 Nm then tighten the bottom nut to 100-120 in-lbs 113-136 Nm final tighten the top nut to 100-120 in-lbs 113-136Nm then tighten the bottom nut of the rear cylinder head exhaust flange to 9-18. 14 - 10 ft. Exhaust Torque specs.

96 - 120 lbs. Joined Nov 6 2006 523 Posts. Just watched this video about checking the bolt torque for exhaust brackets for aftermarket exhaust.

You may have to remove the heat shields in order to access the bolts on all the flanges and use antiseize compound all that heat and corrosion will make things tough the next time. Hi all How much torque is required for the nuts on head pipe flange. 4 Tighten each bolt to 38-42 foot pounds of torque.